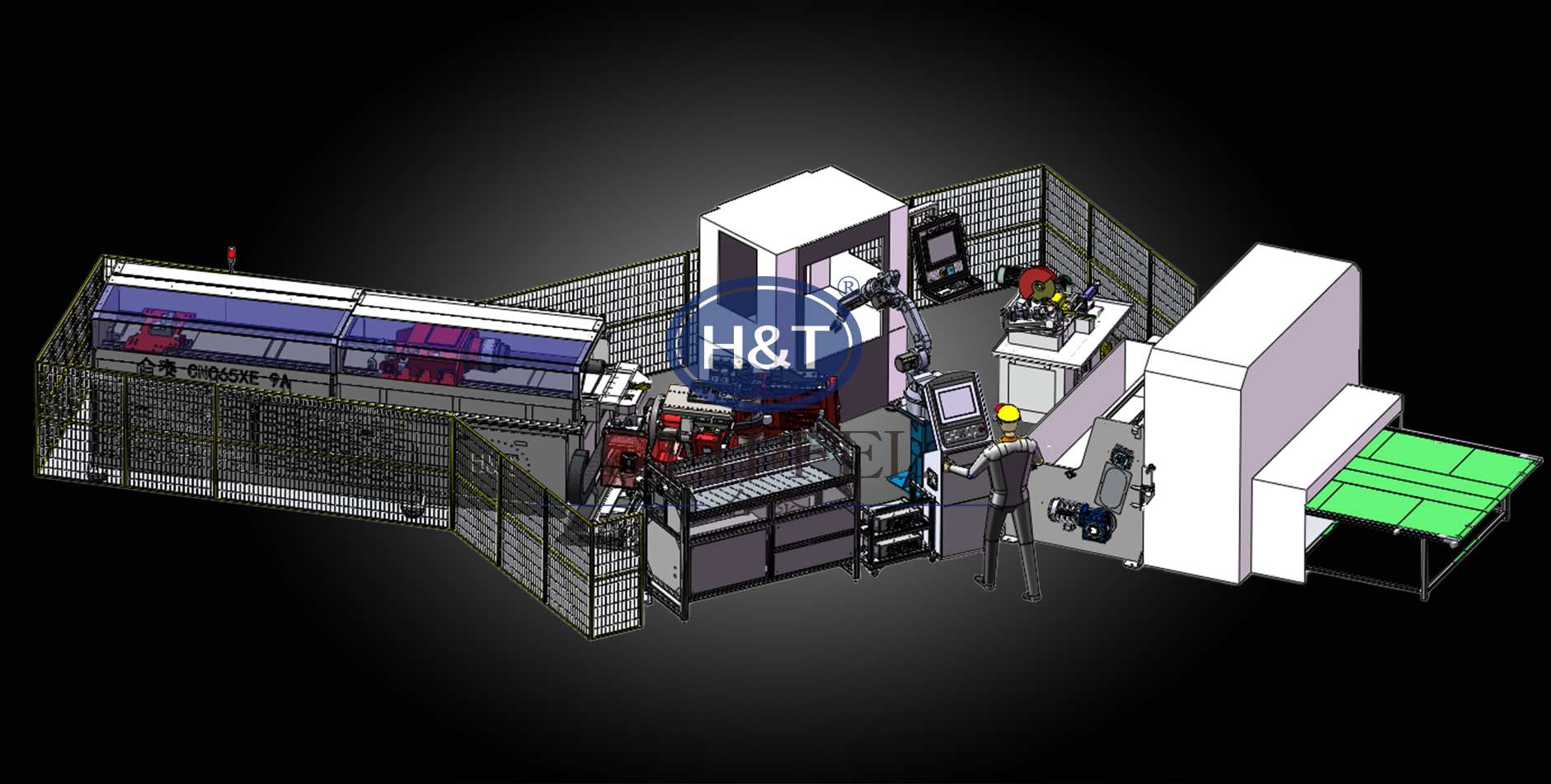

Intelligent aviation catheter production line

- Function Description

- Parameter specifications

- Video presentation

Manually place the pipe fittings on the loading rack, the 6-axis robot sends the pipe fittings to the left and right bending equipment (65XE model), the 6-axis robot takes out the bent products and sends them to the inspection table to detect the length of the tail material, the 6-axis robot sends the workpiece to the trimming and deburring equipment for clamping, the trimming and deburring equipment automatically calculates the length of the tail material and performs one-to-one cutting and trimming of each piece, the 6-axis robot sends the workpiece to the ultrasonic cleaning equipment, the crawling conveyor belt lifts the workpiece out of the water from the cleaning tank, sends it to the air shower equipment, and after drying, it is output to the conveyor table.

Previous article:Smart warehouse + tube forming processing line

Next article:Automatic feeding bending pipe + sawing production line

简体中文

简体中文 English

English español

español Русский

Русский 日本語

日本語