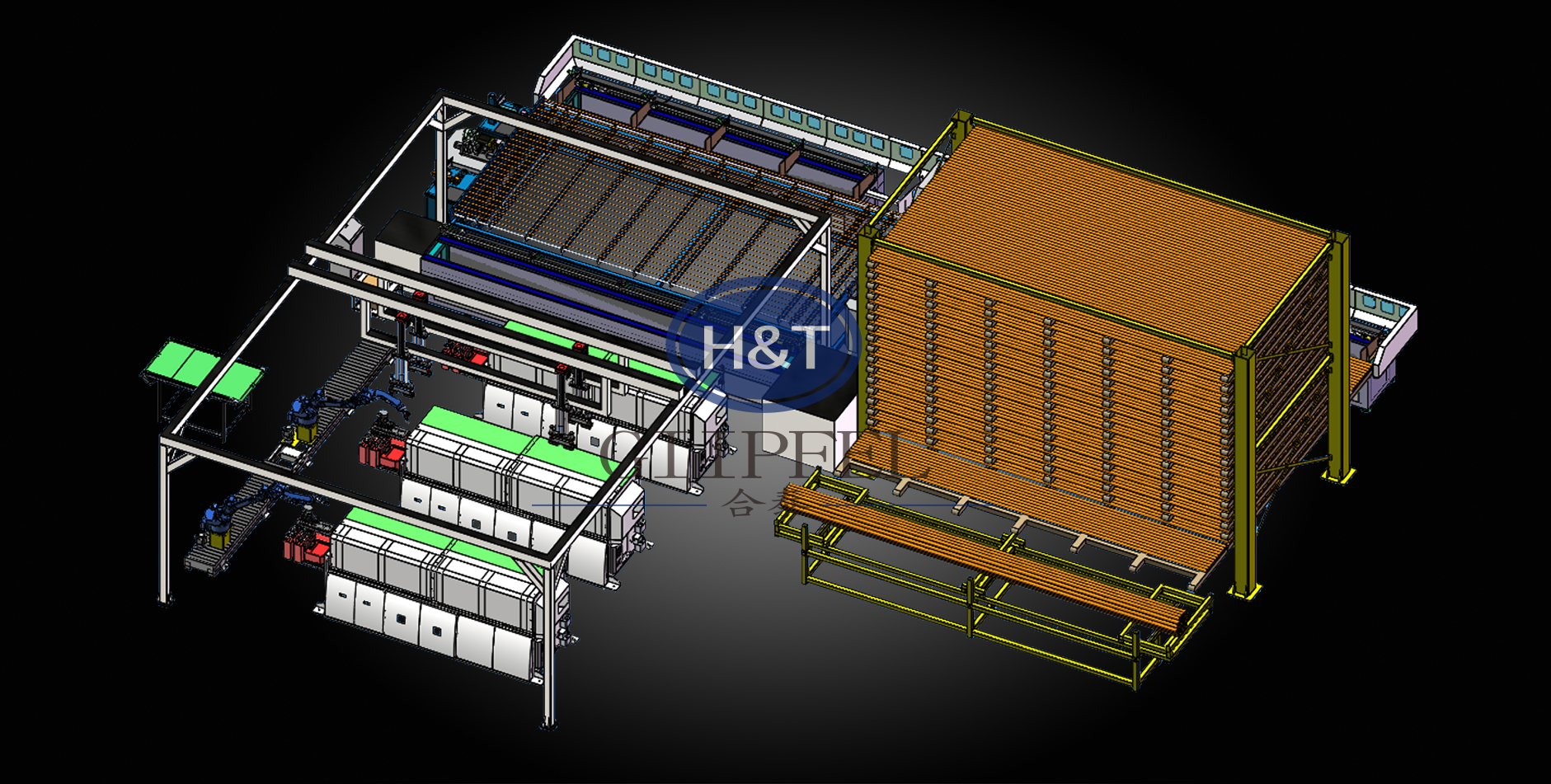

Smart warehouse + tube forming processing line

- Function Description

- Parameter specifications

- Video presentation

1. The production line can complete the intelligent manufacturing of pipe fittings with an outer diameter of φ10-50mm and a length of 200mm-6000mm. It is a digital manufacturing system for the whole process of straight pipe feeding, cutting to length, chamfering the pipe ends, bending and unloading, which is centrally controlled by the central control system.

2. The sorting mechanism equipped with the vertical warehouse loading rack separates the single pipe fittings and sends them to the rotary cutting machine for automatic cutting to length.

3. The cut straight pipe is conveyed by the conveyor belt, firstly coding, chamfering one end flat head, reading the code, and then chamfering the other end flat head. After chamfering, it is sent to the cleaning machine.

4. The truss manipulator grabs the pipe fittings and sends them to the pipe bending machine trolley for pipe bending processing.

5. A seven-axis robot is used, which is responsible for grabbing the bent pipe fittings on the conveyor belt.

Previous article:Wire Bending

Next article:Intelligent aviation catheter production line

简体中文

简体中文 English

English español

español Русский

Русский 日本語

日本語