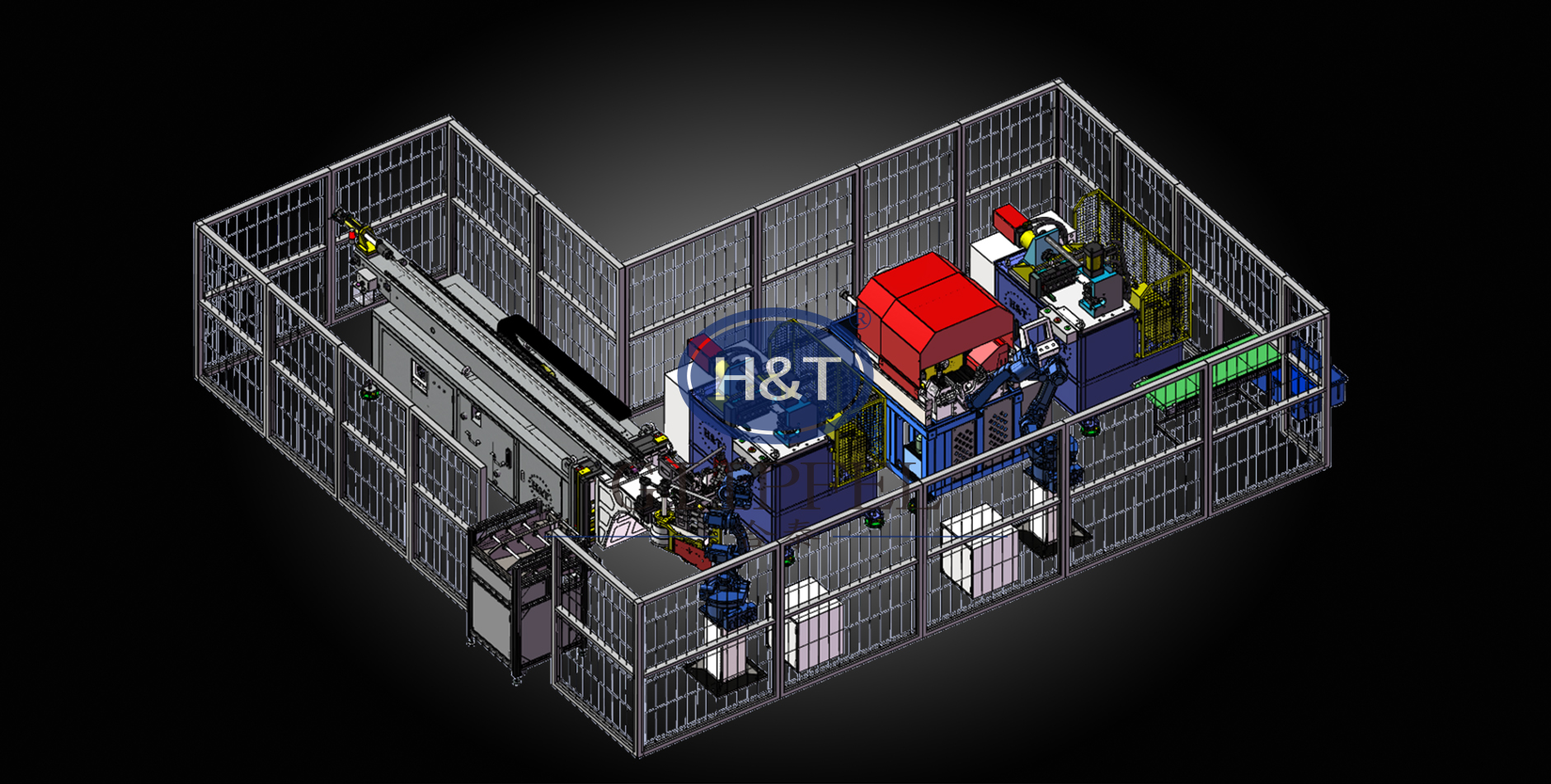

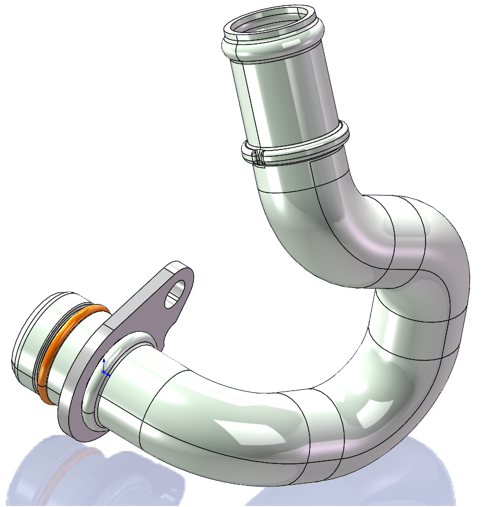

Volkswagen AP550 project bending, upsetting, rotary cutting

2. Processing cycle 30 seconds/piece

- Function Description

- Parameter specifications

- Video presentation

1. The workers only need to stack the pipe fittings neatly in the preparation box, and the loading rack will automatically sort the single pipe fittings.

2. Robot No. 1 sends the pipe fittings to the clamping die of the pipe bending machine for pipe bending. After the pipe bending is completed, robot No. 1 grabs the pipe fittings and sends them to the expansion end forming machine for A-end forming processing (adding flange).

3. After the pipe end is formed, robot No. 2 grabs the pipe fittings and sends them to the clamping die of the groove spinning machine for groove spinning. After completion, robot No. 2 grabs the pipe fittings and sends them to the No. 2 pipe end forming machine for B-end forming.

4. After forming, robot No. 2 grabs the pipe fittings and sends them to the conveyor belt, and then falls into the receiving box.

Previous article:Frame side beam production unit

Next article:Pier head automatic line

简体中文

简体中文 English

English español

español Русский

Русский 日本語

日本語