- Home

- About Giipfel

- Products

- NC Bender

- CNC Bender

- Single head single layer mold pipe bending machine

- Single head double layer, triple layer, multi-layer mold pipe bending machine

- One Way All Electric Pipe Bending Machine

- Single Head Left And Right Shared Pipe Bending Machine Series

- Double machine heads bend left and right

- Double Head CNC Pipe Bending Machine

- Robotic pipe bending

- Pipe End Forming Machine

- Sawing and chamfering

- MC275-315 Series

- MC425HC

- MC485NC-2A

- MC425NC-1A

- IRON PRECISION COLD CUTTING SAW

- MC semi-automatic aluminum cutting machine

- MC high-speed precision aluminum cutting machine

- Three-axis no-tail fully automatic cutting machine

- New rotary automatic line

- Pneumatic single head chamfering machine

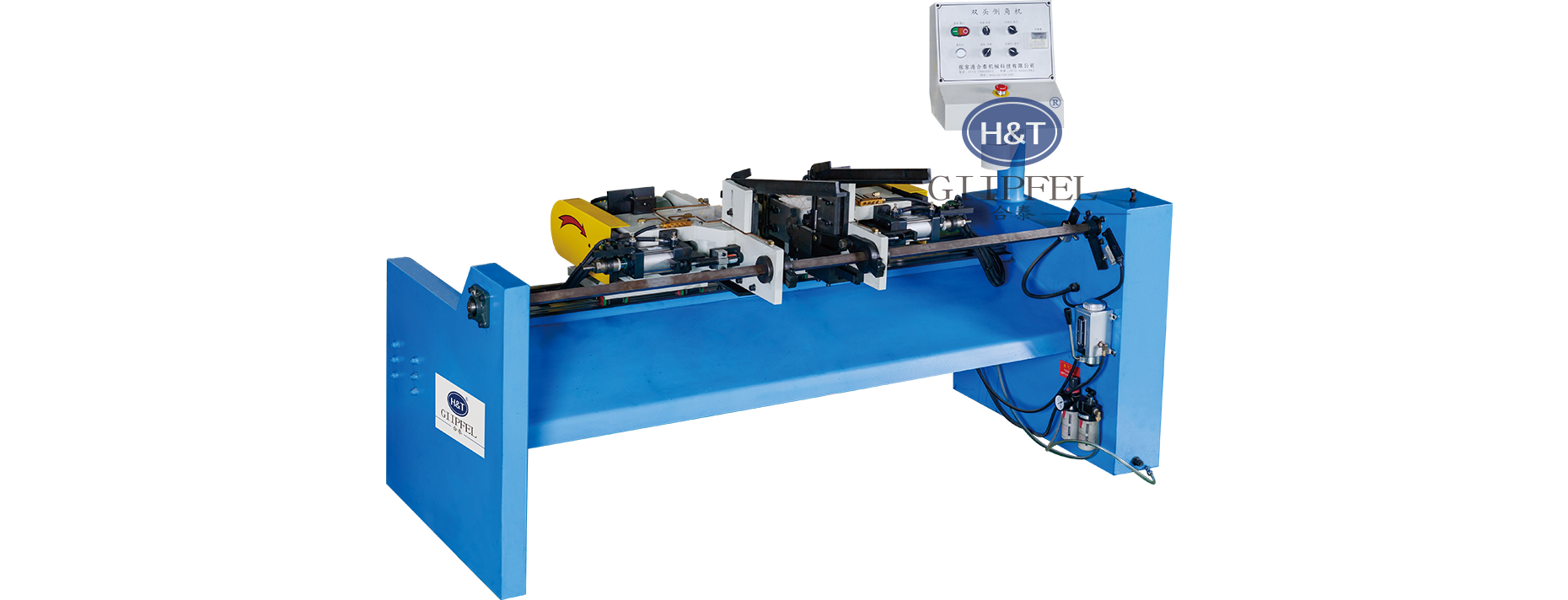

- Double head chamfering machine - short material

- Double head chamfering machine - long material

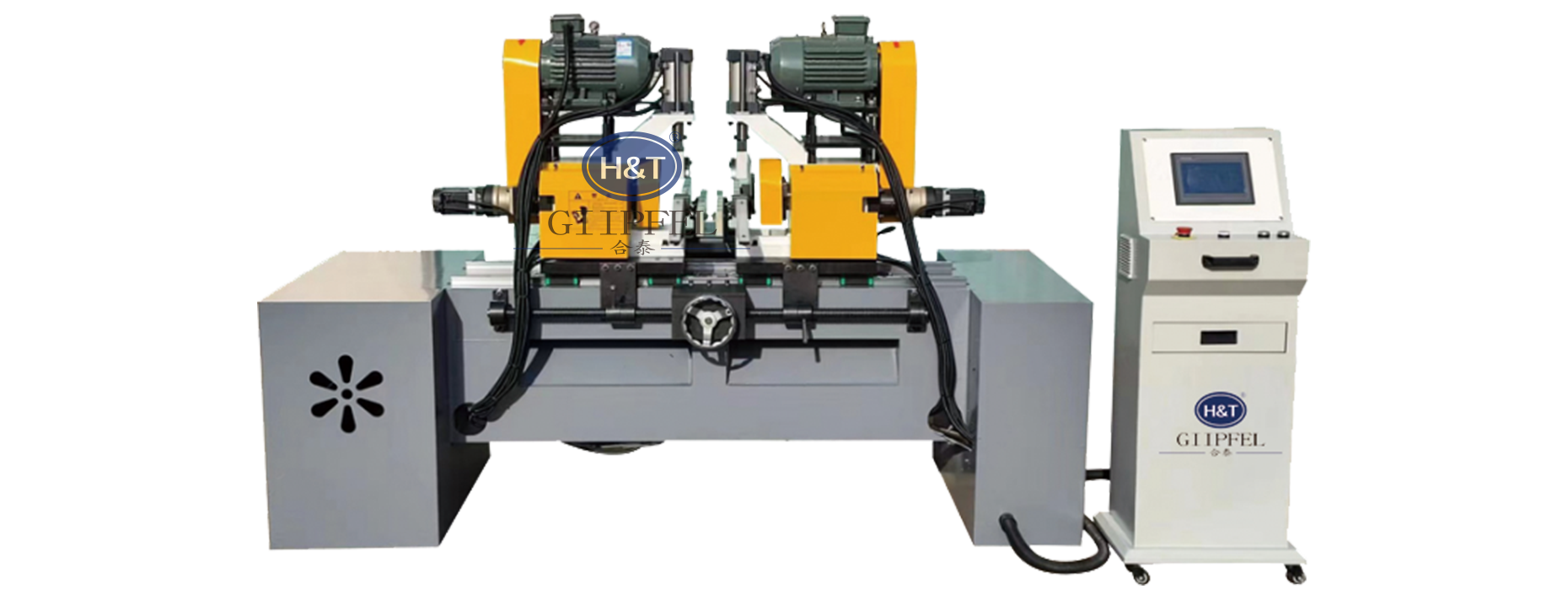

- Automatic double head deburring machine

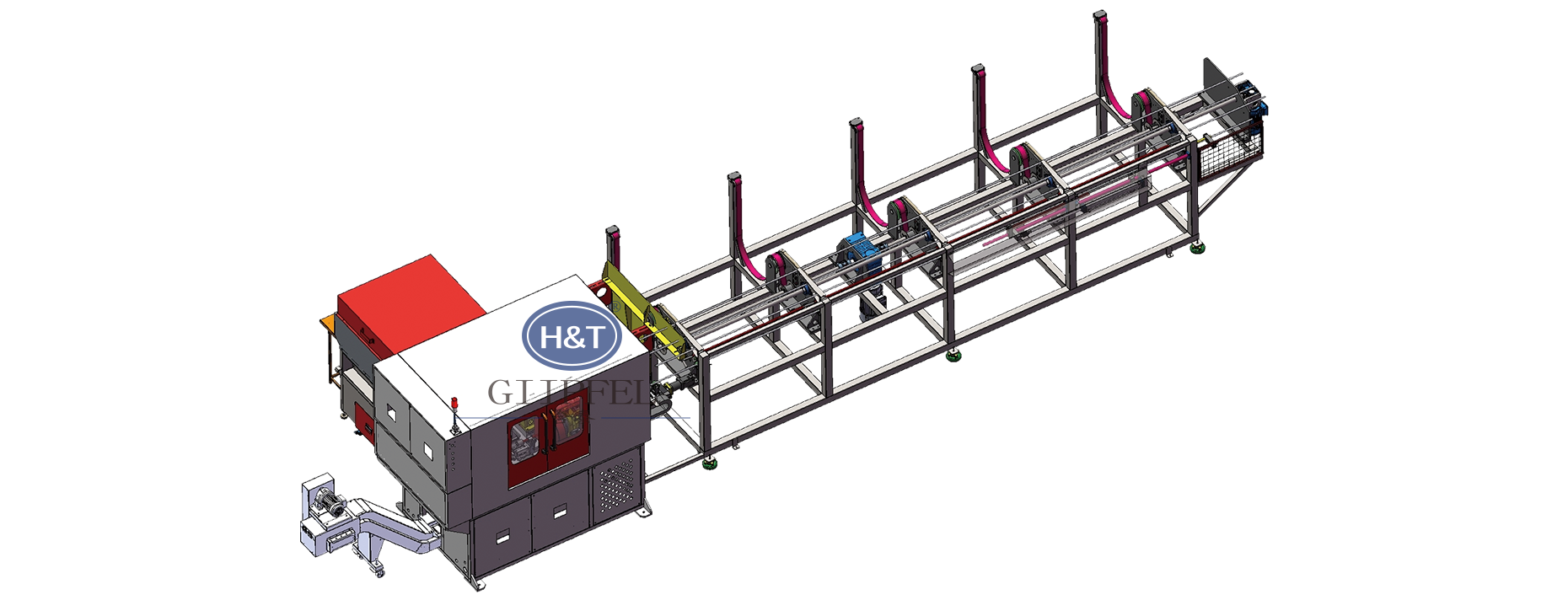

- CUTTING AUTOMATION LINE

- Laser Pipe Cutting Machine

- Wire bending machine

- Special Pipe Bending Machine

- Non-standard Automation

- Automatic feeding bending pipe + sawing production line

- Intelligent aviation catheter production line

- Smart warehouse + tube forming processing line

- Wire Bending

- Cold saw + chamfering machine

- Joint pipe production line

- Pier head automatic line

- Volkswagen AP550 project bending, upsetting, rotary cutting

- Frame side beam production unit

- Double-end upsetting pipe bending automatic line

- Handrail tube & backrest tube automatic line

- Multi-station continuous die bending-seat belt tube

- Serpentine Bend Automatic Line U-Bend

- CNC Bending Machine

- Precision Tube Parts Manufacturing

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Precision tube parts

- Optical measuring machine

- Application Industry

- Automobile Industry

- Construction Machinery

- Aerospace

- Furniture Industry

- Medical Device Industry

- Shipbuilding Industry

- Boiler industry

- Nuclear Power Industry

- Electric Bike/Bicycle

- Locomotive

- Fluid Transportation Engineering

- Semiconductor Equipment

- New Energy and Heat Exchange

- Various Fluid Conveying Pipelines And Pipe Structural Supports

- News

- Contact Us

- Partner

简体中文

简体中文 English

English español

español Русский

Русский 日本語

日本語